Electroplating on Plastic

Need to create a plastic part with a chrome plated finish. At Markon we have been electroplating plastic products for the bathroom industries for over 30 years.

With our specialist knowledge of injection molding plastic parts for electroplating and our own in house plating on plastic line we can offer a one stop shop that takes the hassle out of dealing with multiple suppliers and gives you the quality chrome plated product you require.

The only business in New Zealand that can Mold and Plate plastic all under one roof.

Tooling - Injection Molding - Electroplating on Plastic - Favorable Exchange Rates

Discover the benefits we can offer by doing the complete job for you, all you need to do is place the order and we will look after the rest.

What is Electroplating on plastic?

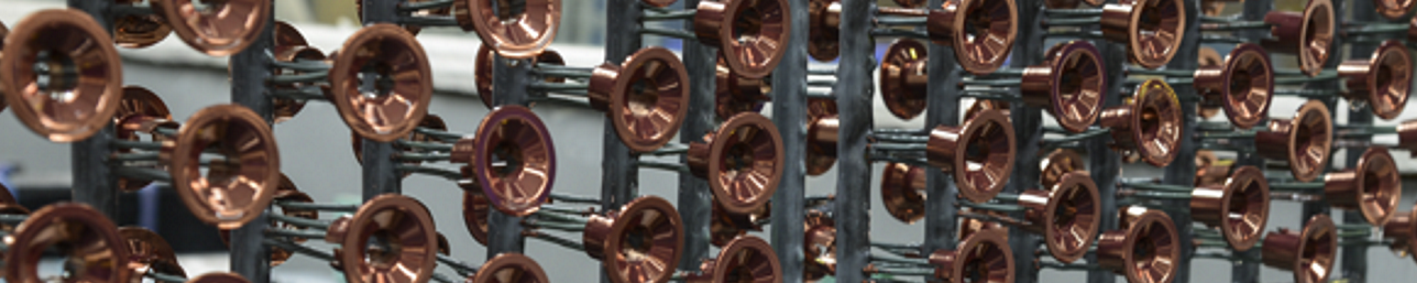

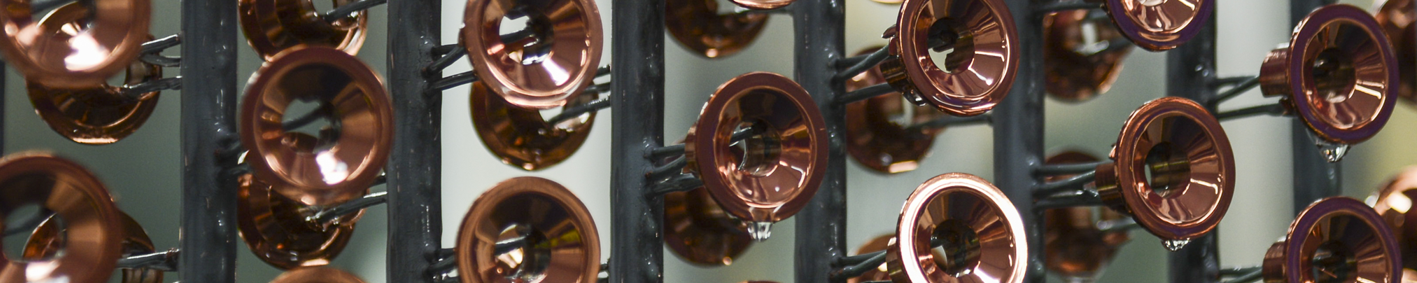

Electroplating is the process in which layers of copper, nickle and chrome are applied to the surface of a plastic part to give it a hard wearing mirror like metallic finish.

Because plastics are non conductors the surface of the plastic must first be chemically treated to make it conductive and create physical bonding sites to enable the layers of metal to lock into and grow on the surface of the plastic in the metal plating solutions.

Plastic parts are loaded on specially designed jigs and processed through 8 specific steps in the plating cycle, taking approximately 2 hours from start to finish.

Advantages of electroplating on plastic

There are several industries that use plastic plating on a regular basis to provide beneficial qualities to their plastic parts, two of which include:

Household Plumbing and Appliances

For many years plastic plumbing products have been used within the industry due to cost savings over brass forgings and other metal options. However, plastic is not always the most aesthetically pleasing material to have within your home. This is why we use chrome plating to enhance the appeal and style of the plastic fixtures for excellent aesthetic results.

Automotive

Internationally, the automotive industry is a major user of plastic on plating technology. Just look at the fixtures and fittings in your car. The ability to injection mold plastic into just about any shape gives engineers a broader range of options when developing vehicle styles that differentiate their company’s products from those of the competition.

Our plating on plastic capabilities

Plating on plastic is a popular choice with our customers that want a hard-wearing attractive metallic finish on their products. Markon has the capacity to provide a cost-effective plating on plastic process that can meet your requirements. Over the years we have worked with many businesses from all around the world, including companies in the US, Canada, UK and Australia. Plus, many other businesses to look at how electroplating on plastic can work for their products and designs.

Depending on your requirements we can offer a complete one-stop molding and electroplating service for your chrome plated parts, contract electroplating or input at product design stage.

How can we help you

If you require chrome plated components for Plumbing & Bathrooms, Appliances, Cosmetic or the Automotive industry, we have the knowledge, experience and expertise to help you. We will promptly respond to your phone or email inquiry and provide technical assistance to help you find the best cost effective solution.

Learn more about what our plating processes can do for you and your products contact us today! We’ll provide you with a no-obligation free quotation for our plating on plastic services.