Injection Molding

When you have a need to produce large volumes of intricate plastic parts, injection molding is the best process to achieve this cost effectively.

At Markon we have been fine tuning our injection molding skills for over 30 years. We can injection mold a wide range of commodity and engineering plastic materials to a high level of quality at cost effective prices.

How Plastic Injection Molding Works

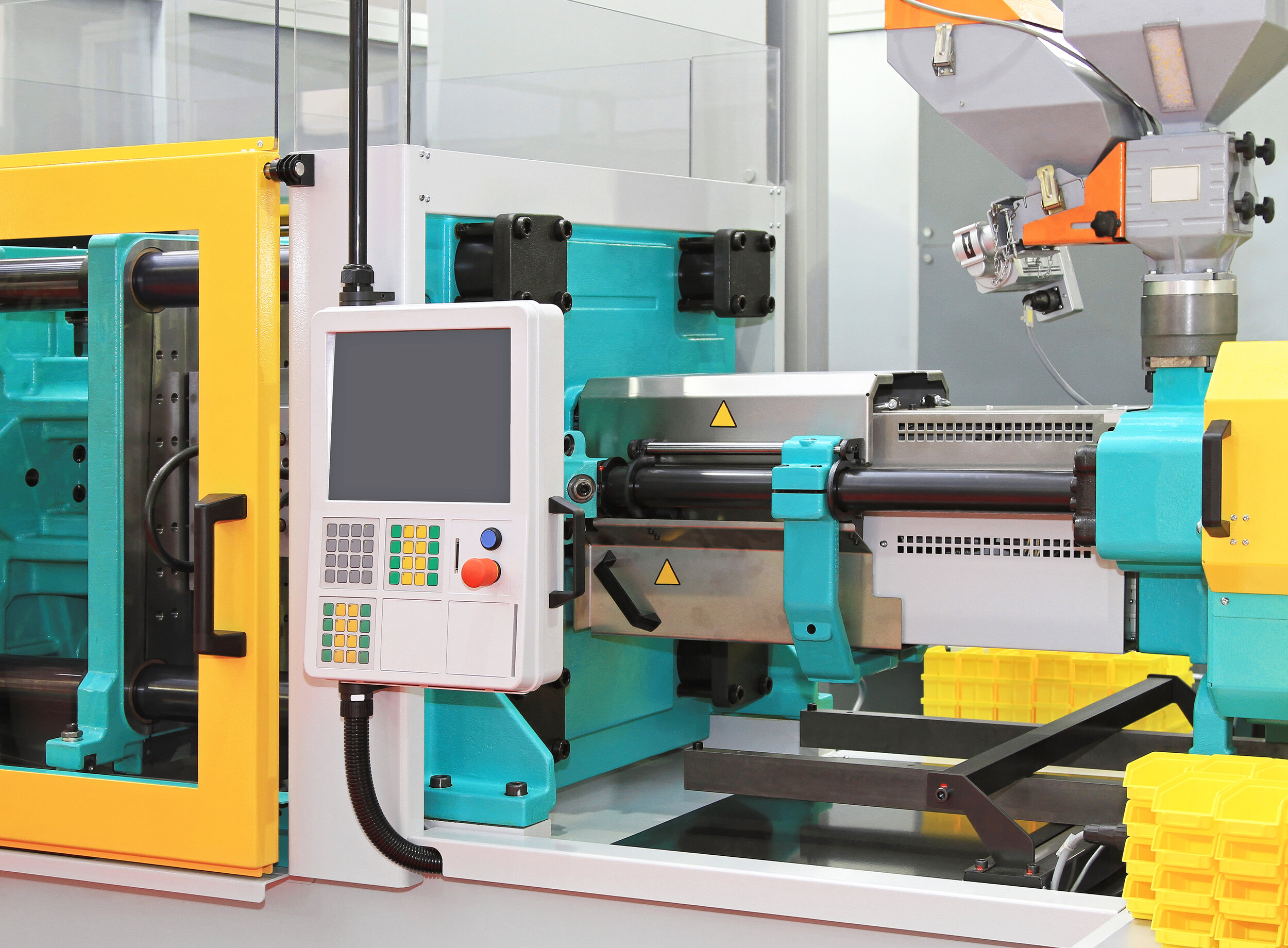

Plastic injection molding is one of the most common ways to produce large quantities of plastic parts for a wide range of commercial and industrial uses.

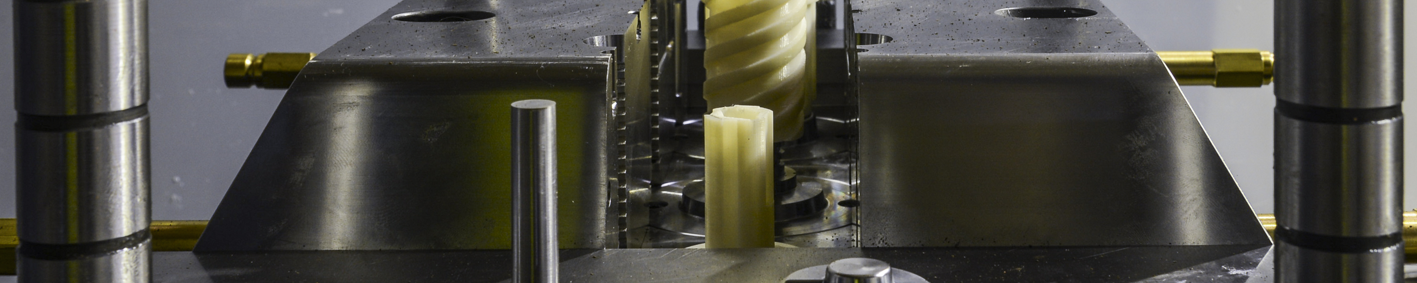

Depending on the component design and application, a specific type of molten plastic resin is injected under high pressure into the cavity of the mold in the injection molding machine and then cooled to form a solid shape.

Advantages of plastic injection molding

The high degree of repeatability and accuracy that you can acheive from this closed loop process makes it the perfect fit for producing large volumes of parts cost effectively.

1. High Efficiency- Make multiple components or groups of products at the same time

2. Complex Parts - Produce parts that would be difficult to machine due to their shape and quality requirements

3. Repeatability - The closed loop process means each part will be almost identical

4. Flexibility- Select from a wide range of plastic materials that can be colored specifically for your requirement

5. Low Waste - with the ability to reclaim and reuse plastic material depending on application the overall waste is minimal

6. Cost Effective - with very little labour and high efficiency this process is the most cost effective method of producing plastic parts.

our injection molding capabilities

We can provide our clients with full custom injection molding service, including injection mold tool design and build if required, or we can run your own plastic injection molds in our plant and care for them as if they were our own.

We have the plant, capacity and experience to cater for your needs, whether that be high volume commodity type products or more technical engineering products, you will find our experience in manufacturing our own products will give you the peace of mind that we know what we are doing.

If you have a product you need injection molded, we’ll help you achieve it. You’ll find we are experts in processing a wide range of materials, including:

PVC - rigid and flex grades

ABS - Electroplating grade

ABS - Standard grades

POM

Nylon

Polypropylene

Santoprene

And other engineering materials

How we can help you?

Having problems manufacturing an existing part, got a new idea you need advice on, need a quote to manufacture a plastic component, you may be surprised how cost effective we are